During the mold trial, molding defects are often happened without a certainly forecast, hence a good mold trial engineer should have rich experience to judge the reason as fast as possible, as the cost is increasing along the time spent on injection machine.

Here our team accumulated some experience, if this sharing can show a little bit hint to benefit your similar problem solving, we will be very happy.

Here we talk about three marks: “Burnt Marks”, “Wet Marks” and “Air Marks”.

Features:

·Periodically appearing

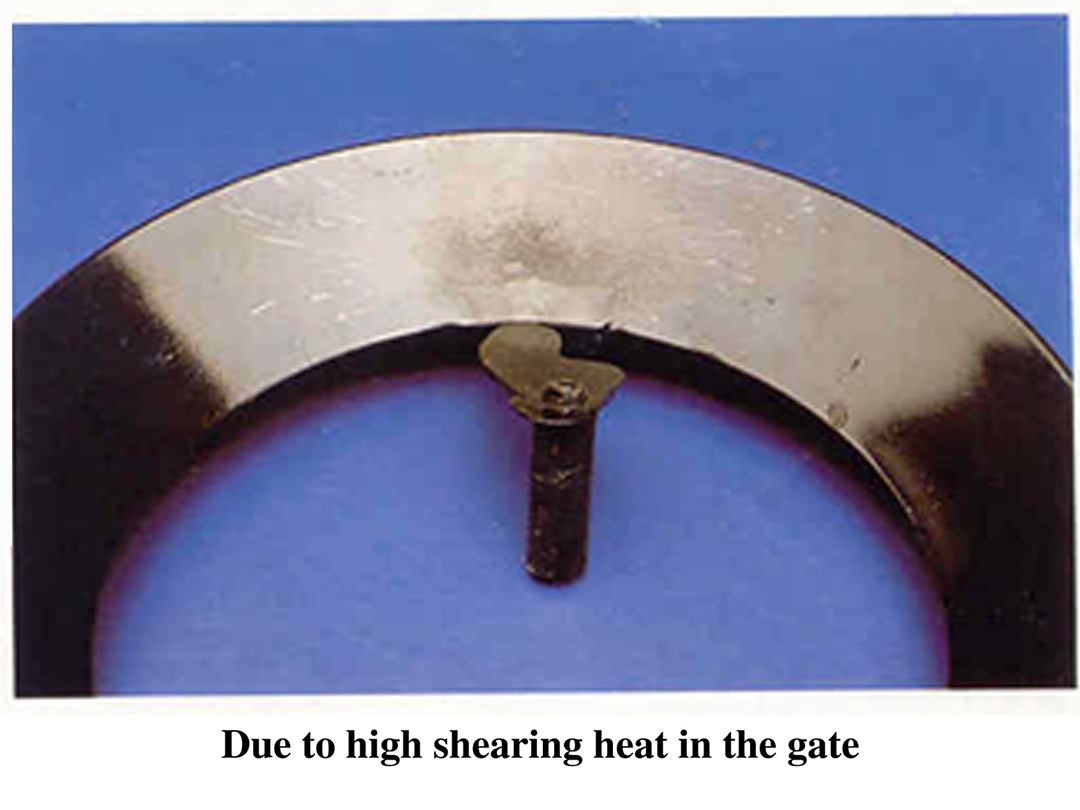

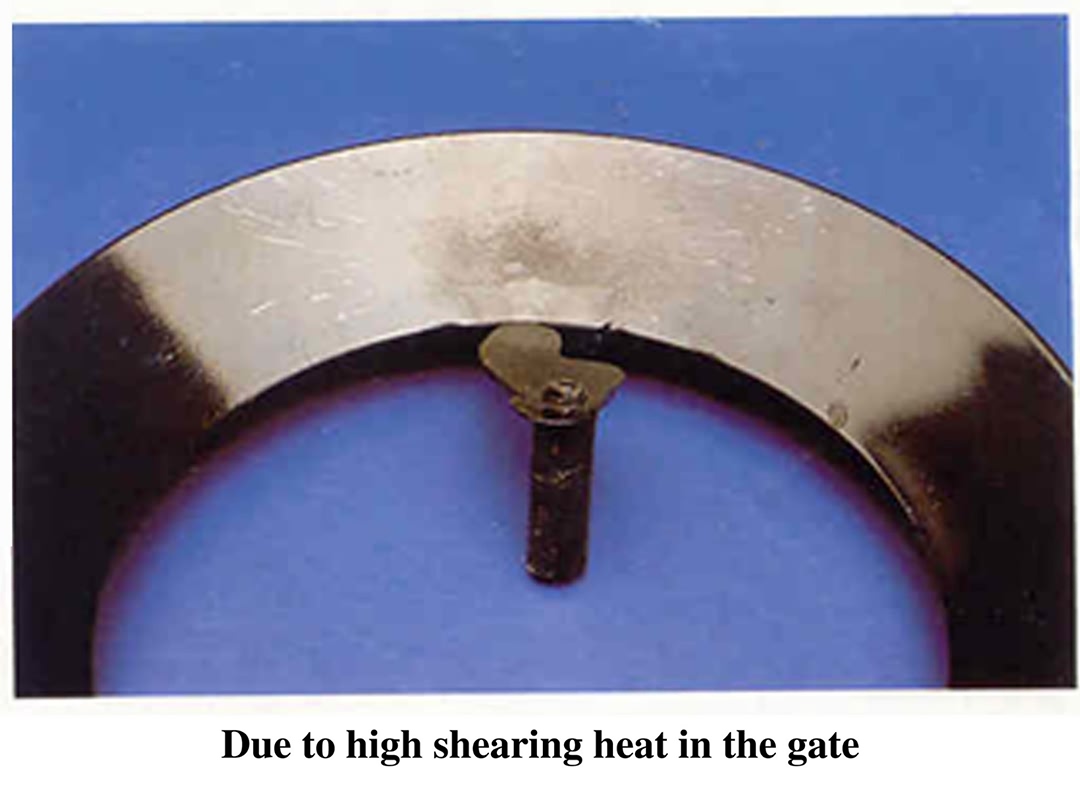

·Appearing in the narrow cross section or air trap position

·The melting temperature is almost the upper limit of the injection temperature

·The defect has a certain effect by reducing the press screw speed

·Plasticization time is too long, or stay in the front area of the press screw too long

·The recycled plastic material be used excessive or material has been melted several times before

·Appearing in the mold with hot runner system

·Mold with closed nozzle (Shut Off Nozzle)

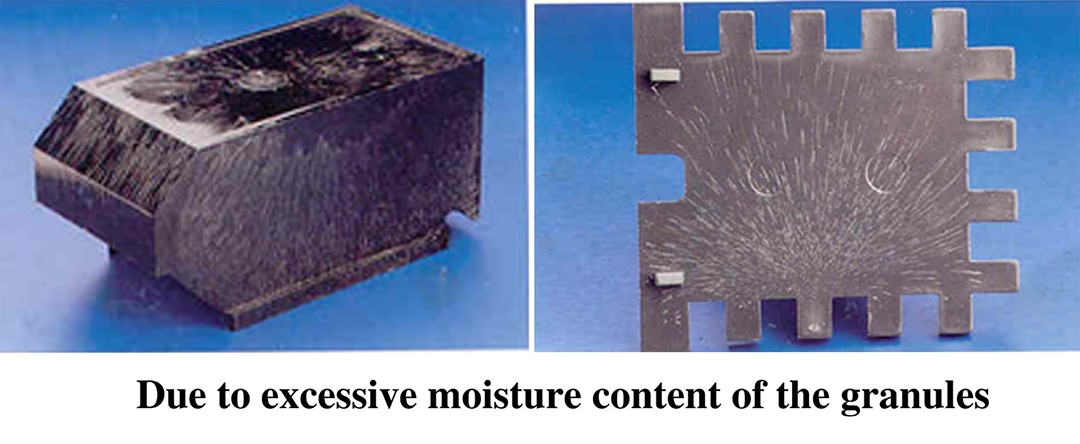

Features:

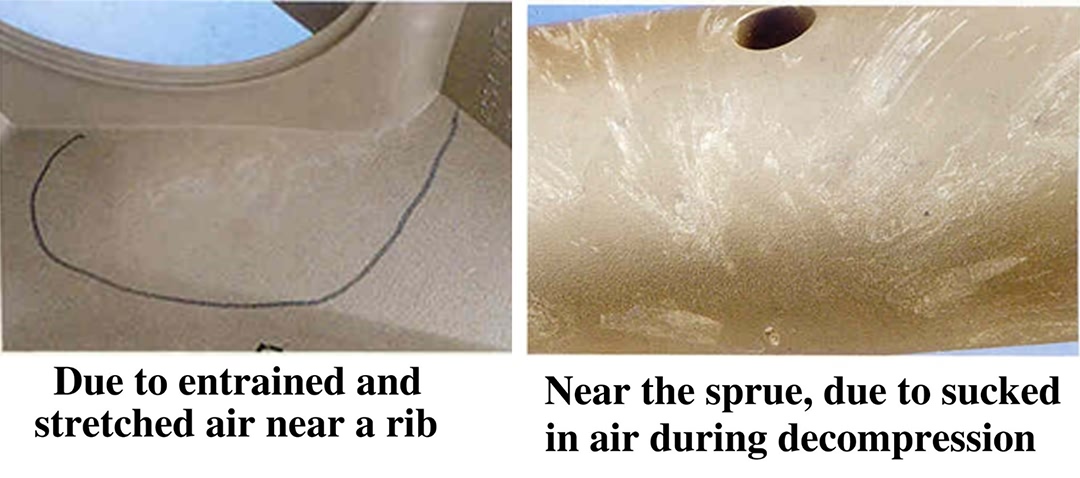

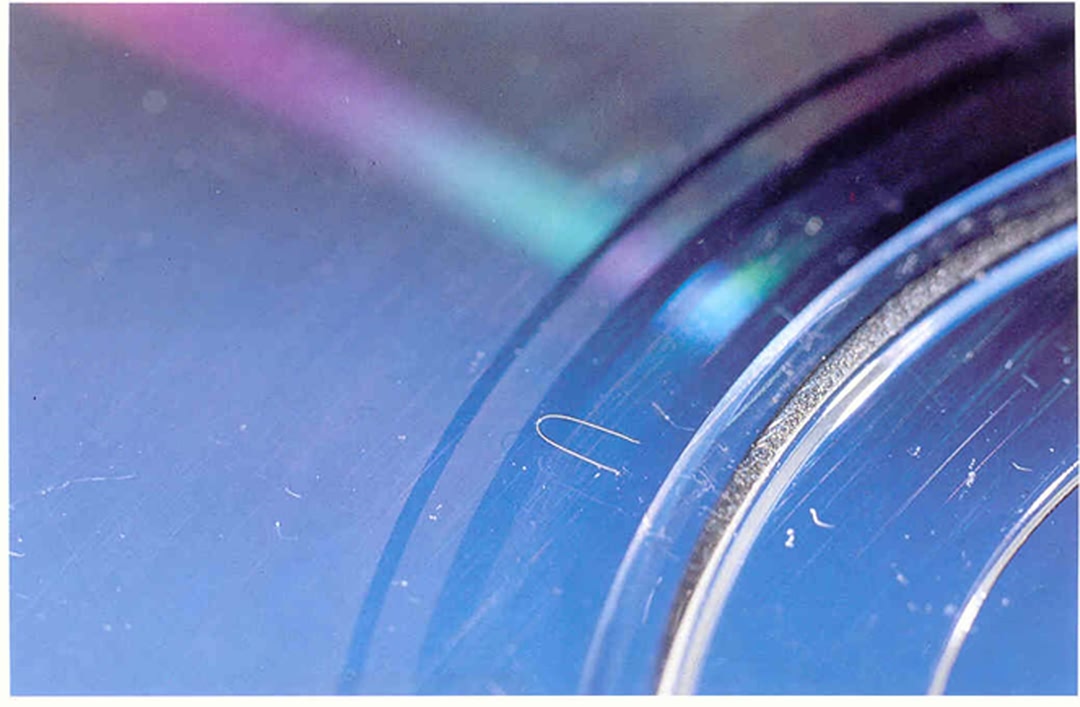

3、Air Marks

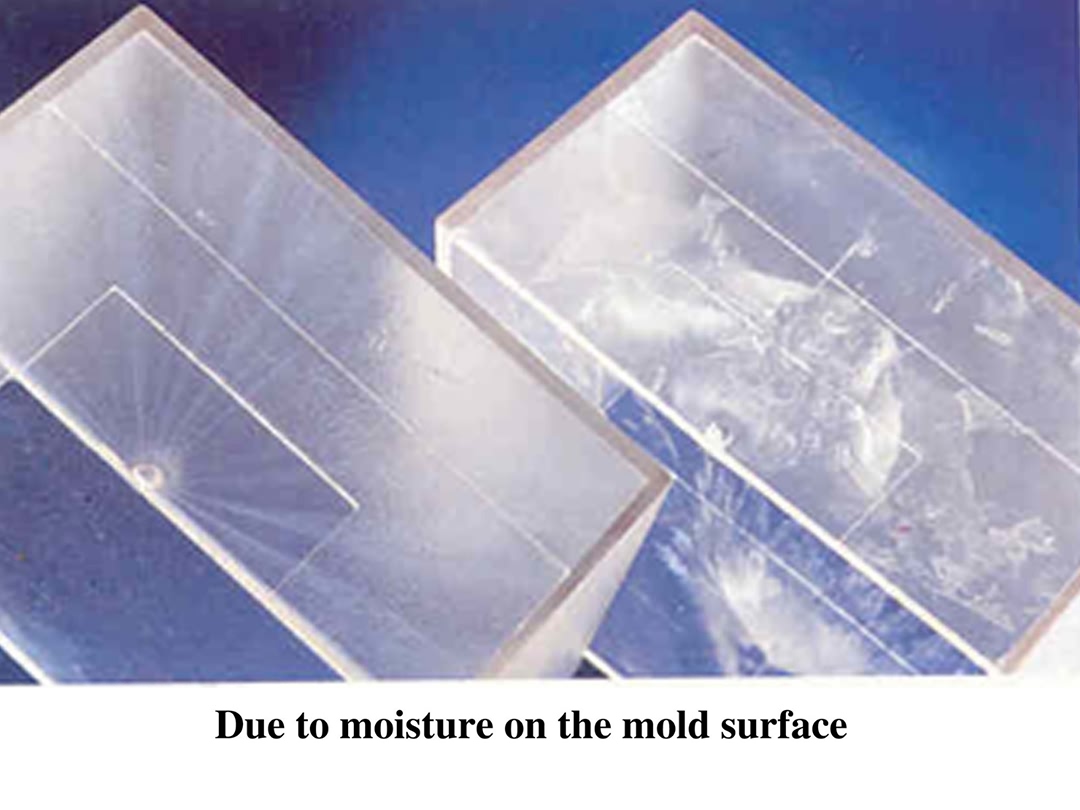

In general, the air marks’ shapes are rough, with silver or white color, often appear in the spherical/curved surface, ribs/wall thickness changes areas or in the vicinity of nozzle, the gate entrance usually appears thin layer of air marks; Air marks are also appear at the engraving, for example: text engraving or depression area of place.

Except above types, we also have “Glass-fiber marks” and “Color marks” on the part surface.so in future, more molding defects experience will be shared with dear friends on linkedin, if you have different opinions about my post, please kindly let me know your comments, as we know, linkedin is always a good platform for us to share, learn and improve!

Post time: Oct-26-2020