May 15th, 2017- molds shipment

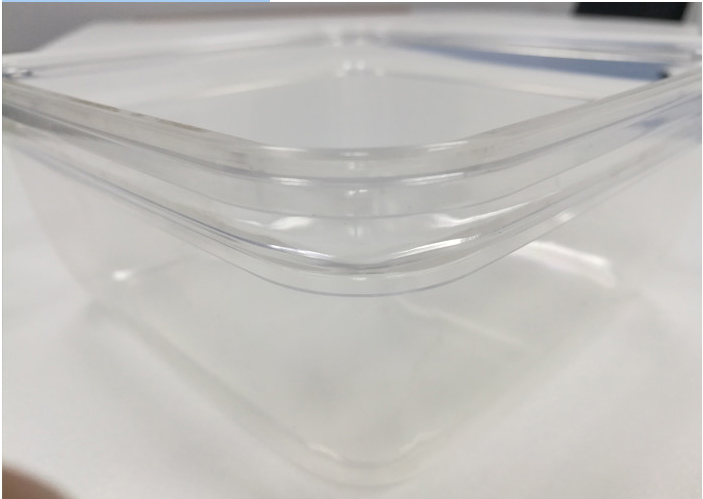

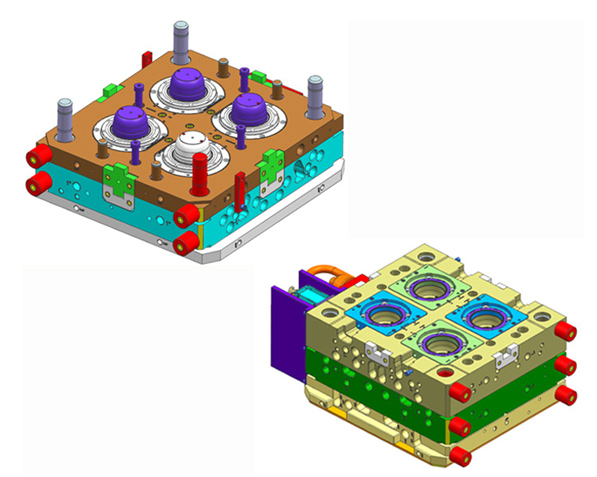

After several months hard working, a batch of household (food-boxes) molds were shipped to customer. As the parts are transparent (as above picture shown), and customer have a high-level requirement on the parts appearance. Our engineering team did a lot to conquer the parts air venting problem. Finally, our dear customers were happy with these molds performance, thanks so much for your support My dear colleagues, you are all my hero. thanks for all your effort! Lol…

Above are the parts injected by the mold which we made.

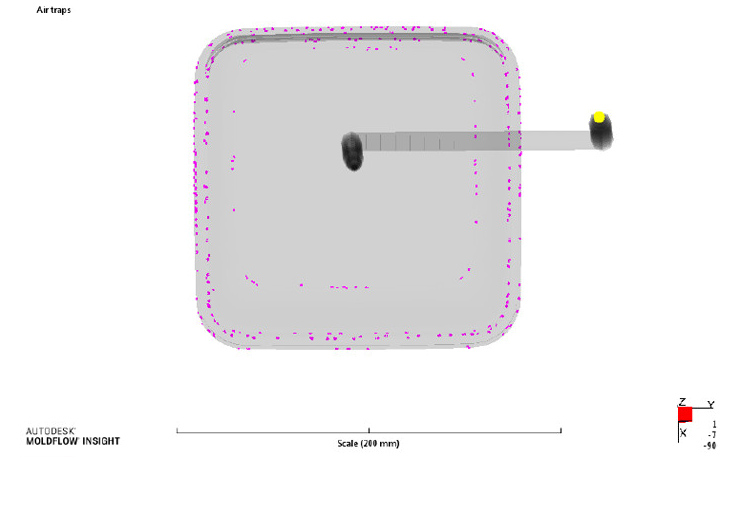

May some friends have the experience about transparent parts mold manufacture. as we know, these bowls are not only appearance parts, but also transparent material molded. So, its appearance is very particular, hence air venting, short-shout and part filling defects are must be avoided. In that case, how to design the inserts to have a good venting status become the key to ensure the finally mold quality, of course setting a good press parameter is also a very important assistance.

Especially there are 3 step geometry on the part, hence the air venting become a big problem. should experience mold maker know what a case we faced!

ok, let us review the complete process of molds making.

Step 1: Customer placed the order with part data.

Receiving the part “2D/3D data”, “injection machine size” and “part material parameter” etc.

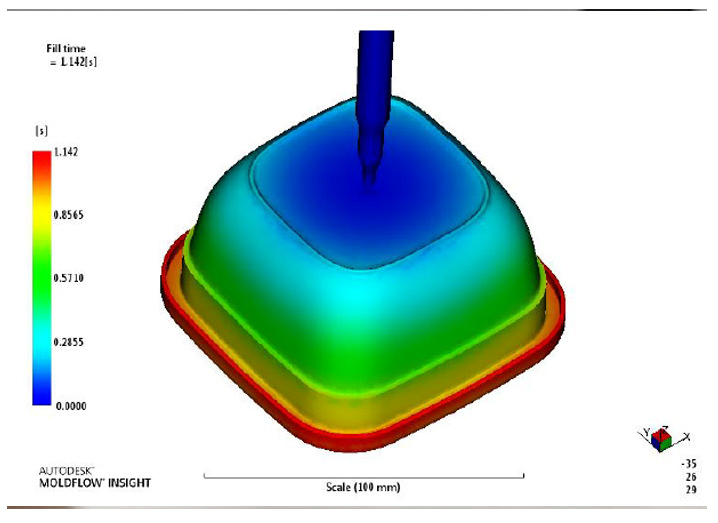

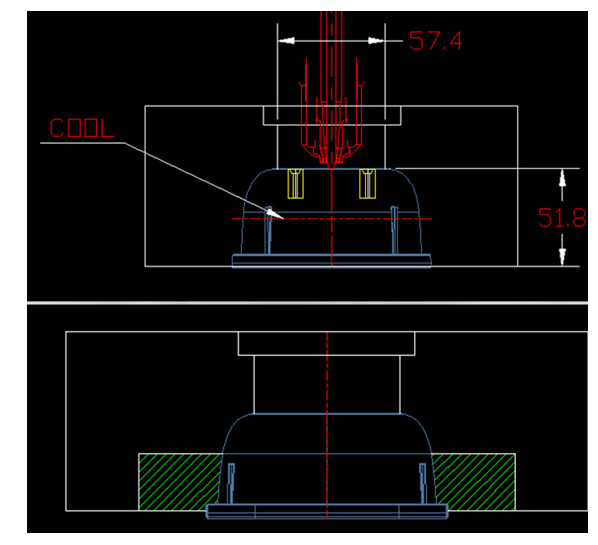

Step 2: Mold-flow and DFM report

Doing the mold flow analysis, according to analysis result to do the DFM report. Communicated with customer to determinate the mold design proposal.

Step 3: Mold designing Our mold designers will complete the design according to the mold flow and DFM report. Then submit the design to customer for validation.

Step 4: Mold manufacture and assembly After getting the customer approval about the finally mold design, we start to steel machining and parts assembly.

Step 5: Mold trial

Mold trial is the most important process to inspect the mold manufacture quality, try to explode the mold issues then solve it at our plant, ensuring the mold could be produced well at customers’ injection plant.

Step 6: Mold optimizing.

According to the mold trial result, we will do the mold improvement work to optimize the mold problems. Normally we will have the mold tested 1-3 times to get the mold completely reach customer requirement.

Step 7: Shipment.

After getting the customer approval for mold shipment, we would package the mold well then contact the logistic forwarder to deliver the mold to customer.

Post time: Jul-26-2020