1. The plastic machine cannot open/close the mold

Reason analysis: the production safety door of the plastic machine is not closed properly, and the safety protection device does not receive a signal. For example, the safety lever travel switch of the plastic machine does not receive a signal, such as the SGM620 tailgate handle, and the plastic machine malfunctions; mold guide post position

Set deviation or deformation; if the plastic product is not taken out, the solution is to re-close the safety door; check the plastic machine travel switch; if there is any problem, ask a professional to repair it; take out the product.

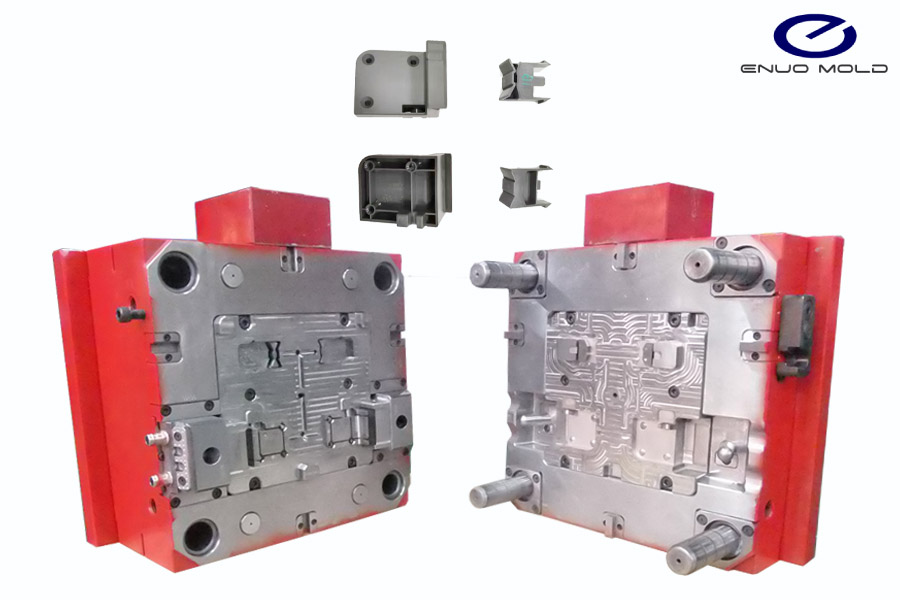

Mold opening: First, the slider core is pulled, and the travel switch sends a signal that the slider has retracted to a sufficient position; second, the injection molding machine receives the travel switch signal and starts to push the ejector plate to eject the ejector from the mold. Clamping: First: After the ejector plate is driven down by the injection molding machine, the inclined top is reset, and the travel switch sends a signal; second: the injection molding machine receives the travel switch signal, and the slider resets to complete a mold clamping process.

2. The plastic mold leaks water, air, and oil

Cause analysis: waterway joints are damaged; mold core waterway is corroded; joints are not locked; sealing ring is aging; solutions; replace water joints; repair molds, redesign waterways or make damaged parts; tighten joints; replace sealing rings;

3. The thimble of the electroforming mold cannot be ejected

Cause analysis: thimble component seizure: such as thimble, back stitch, inclined top, etc. seized or broken; ejector pin failure, sliding teeth, oil cylinder damage; safety protection device works, such as the travel switch does not receive a signal; solution *Replace damaged parts; check whether the movement of the ejector plate and related mechanisms of the malfunctioning parts is smooth, the three-compartment throttle cover is often seized, and the ejector plate is not hard enough to be hardened, so make up the oil groove for the inclined top; check whether the injection molding machine is faulty.

4. Dip mold for plastic products

Cause analysis: poorly polished mold cavity; insufficient demolding angle; product undercut, and the design is not handled properly;

The skin texture is too deep (rear protection bracket after 410); the product structure design is unreasonable, such as the b53_b51 flow trough connecting rod; the mold temperature is too high, and the rigid material is deformed; the solution is to polish within the reasonable tolerance of the product and increase the demolding angle; increase the pull Needle or undercut; re-improve the position of the parting line; change the production process of plastic products and molds.

5. The surface of the plastic product is top white

Reason analysis: insufficient number of ejector pins; insufficient demolding angle; unsatisfactory ejector position; high mold temperature; unreasonable process setting; solution; polishing and increasing the demolding angle within reasonable tolerances of the product; adding a material-drawing pin or reverse Buckle; re-improve the position of the parting line; change the process; spray release agent;

6. Strains

Reason analysis: unreasonable mold structure design; unreasonable selection of parts materials; insufficient polishing; back mold bone position inversion; solution to strengthen polishing; change the inclination of drag mold; improve and optimize mold structure design;

7. The thimble of the electroforming mold is broken

Reason analysis: the thimble design is unreasonable; the thimble material is poor; the mold is deformed; the movement of the thimble plate and the tube position is unstable; the solution; the replacement of high-quality materials and the increase of the material thickness; the increase of the guide post on the thimble plate; the improvement of the process; the increase of the diameter and the matching of the thimble Smooth

8. Mould position components burned to death

Cause analysis; slider wear; slider bead wear; mold deformation; improper material selection or handling;

Solution; Replace high-quality materials and hardened treatment; Replace the bead; Improve the structure process; Replace the slider;

9. Electroforming plastic mold collision

Reason analysis: spring: thimble, sliding block, inclined top, ejection and retraction are not in place; positioning steel ball or limit block is damaged, causing the sliding block to crash; the insert is detached; the product is not taken out and the mold is closed; the solution; re-wiping Mold, matching mold; replace positioning steel ball or

Limit block; strengthen the fixed insert; take out the product to close the mold;

10. The center of the cylinder is not in place

Reason analysis: ejection; distance is too small; inclined top or slide block stroke is insufficient; structure design is unreasonable; product deformation; solution; re-clamping and matching of molds; replacement of positioning steel balls or limit blocks; strengthening of fixed inserts; increase Ejection distance.

Post time: Aug-02-2021