The difference and connection between mold and lathe:

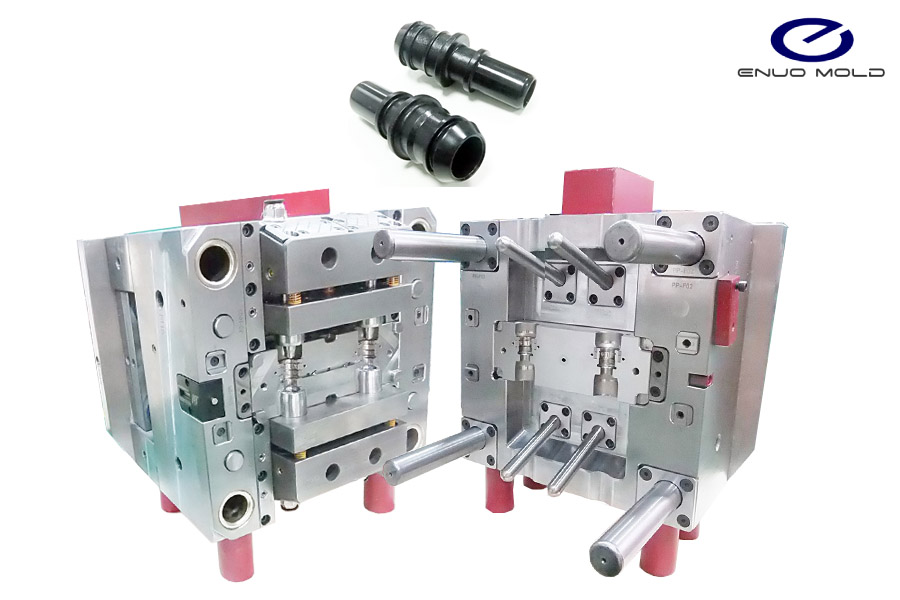

1. Mold (mú jù), various molds and tools used in industrial production to obtain the required products by injection molding, blow molding, extrusion, die-casting or forging molding, smelting, stamping and other methods. In short, a mold is a tool used to shape objects. This tool is composed of various parts, and different molds are composed of different parts. It mainly realizes the processing of the shape of the article through the change of the physical state of the formed material. Known as the “Mother of Industry”.

2. A lathe is a machine tool that mainly uses a turning tool to turn a rotating workpiece. Drills, reamers, reamers, taps, dies and knurling tools can also be used on the lathe for corresponding processing.

3. The mold is a tool used to shape objects. This tool is composed of various parts, and different molds are composed of different parts. It mainly realizes the processing of the shape of the article through the change of the physical state of the formed material. In the forming process of punching, forming stamping, die forging, cold heading, extrusion, powder metallurgy parts pressing, pressure casting, and compression molding or injection molding of engineering plastics, rubber, ceramics and other products, it is used to make The blank becomes a tool for parts with specific shapes and sizes.

4. The lathe is a machine tool that mainly uses turning tools to process the rotating surface on the workpiece. Applied disciplines: mechanical engineering (first-level discipline); cutting process and equipment (secondary discipline); metal cutting machine tools-various metal cutting machine tools (secondary level) Subject).

5. Where the two intersect, a lathe may or may not be used in the mold making process.

Post time: May-24-2021